Learning Objective

- Different types of aerosol systems

Solution System

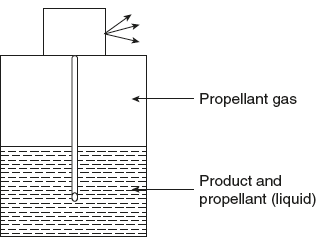

These are also referred to as the two-phase systems—a liquid and a vapor phase. They consist of a solution of active ingredients in pure propellant or a mixture of propellant and solvents. If the active ingredient is soluble in the propellant, no other solvent is necessary. These types of systems are easy to formulate. The propellant used depends upon the type of spray desired. Propellant 12 or A-70 produces very fine particles. A blend of propellant 12 with other propellants can also be used. If propellants having vapor pressure lower than that of propellant 12 are added in the blend, the pressure of the system decreases resulting in larger particles. Lower vapor pressure can also be achieved by addition of less volatile solvents such as ethyl alcohol, propylene glycol, ethyl acetate, glycerin and acetone. These types of sprays produce wetness and hence suitable for topical aerosols where a film of medicament will be formed on the surface. Larger particles reduce the danger of inhalation of particles by formation and subsequent inhalation of airborne particles. Diagrammatic representation of a two-phase solution system is shown in Figure 12.16.

Figure 12.16 Diagrammatic Representation of a Two-phase Solution System

The system can be exemplified by the following general formula:

| Weight% | |

| Active ingredients | 10–15 |

| Propellant 12/11 (50:50) q.s | 100 |

The ratio of propellant 12 and 11 or propellant 12 with any other propellant such as propellant 114 can be used for other applications such as oral inhalation. As the pressure increases, the choice of container also needs to be changed.

Hydrocarbons in topical aerosol pharmaceutical preparations are used as follows:

| Weight% | |

| Active ingredients | 10–15 |

| Solvents such as ethanol or propylene glycol | 10–15 |

| Distilled water | 10–15 |

| Hydrocarbon propellant A-46 | 55–70 |

Water-based System

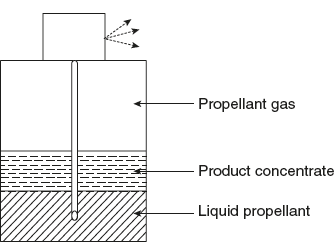

These “water-based” aerosols are emitted as spray or foam depending on the formulation. The formulation consisting of an emulsion of active ingredients and other solvents produce a spray. When the product is dispensed, the propellant vaporizes and disperses the active ingredients into minute particles. Three phases are formed—liquid propellant, product concentrate and vaporized propellant. Ethanol is used as a co-solvent to solubilize some of the propellant in water.

Diagrammatic representation of a three-phase water-based system is shown in Figure 12.17.

Figure 12.17 Diagrammatic Representation of a Three-phase Water-based System

Surfactants have been used to a large extent to produce a satisfactory homogenous dispersion. The surfactants having greater solubility in non-aqueous solvents have been found to be most useful. In general, about 0.5 to 2.0% of surfactant is used. The propellant content varies from about 25 to 60%, but can be as low as 5% depending on the nature of the product. When the propellant concentration is small and the water content is large, a mechanical breakup actuator along with a vapor tap is used, if a fine particle spray is desired.

The aquasol system is one such example where the propellant concentration is less and water content is more. The product is dispensed in a fine mist or spray and since the propellant is present only to a small extent, it does not produce any chilling effect. The aquasol system utilizes a large percentage of water in the formulation. The system is a three-phase system but unlike the other three-phase systems, aquasol permits the use of fairly large quantities of water in the formulation. Moreover, the amount of hydrocarbon propellant is relatively less, the resulting spray is non-flammable and the product is economical.

Suspension System

These systems involve the dispersion of active ingredients in the mixture of propellants. Like conventional suspensions, surfactants or suspending agents are added to the system to decrease the rate of settling of the dispersed particles. Such systems are mainly used for oral inhalation aerosols.

Stability problems associated with disperse systems such as caking, agglomeration and particle size growth can also be observed with aerosol disperse systems. In several cases, the particles may adhere to the walls of the container. Agglomeration may result in valve clogging and thus may lead to inaccurate dosing.

In order to overcome these problems, the following measures can be used:

- Lubricants such as isopropyl myristate and oleic acid provide slippage between the particles and also lubricate the components of the valve.

- Surfactants can be used to disperse particles.

- Dispersing agents such as oleic acid and lecithin help in keeping the suspended particles from agglomerating.

- The particle size of metered-dose inhalant should be between 2 µm–8 µm, while those for topical aerosols should be between 50 µm–100 µm. This is to prevent blocking of the aerosol valves.

- The moisture content of both the propellant and the suspension should be below 300 ppm. Higher moisture levels generally result in particle agglomeration and thus strict control over the manufacturing conditions should be exercised.

- To overcome particle size growth during the shelf life of the product, the initial particle size can be reduced to less than 5 microns.

- The density of the propellant and the suspension are equalized.

- To reduce valve clogging, vapor tap valves have been used with dispersion aerosols. The escaping of the propellant in the form of vapor helps in clearing the valve of solid particles.Example for a formulation for oral inhalation containing a steroid: Steroid compound8.4 mgOleic acid0.8 mgPropellant 114.7 gPropellant 1212.2 g In the above formulation, oleic acid acts as a dispersing agent for the steroid. It reduces particle growth and agglomeration. In addition, it also performs as a valve lubricant and prevents metered valves from sticking in the open position.

Emulsion System

These kinds of systems are suitable for topical aerosols. The emulsion systems may be of the following categories.

Foam systems: The active ingredient, aqueous or non-aqueous vehicle, surfactant and propellant are dispensed as stable or quick-breaking foam. The propellant generally forms the internal phase of an Oil-in-water (O/W) emulsion. The foam may be advantageous for various applications involving irritating ingredients or when the material is applied to a limited area. The type of foam systems may be aqueous stable foams, non-aqueous stable foams, quick-breaking foams and thermal foams.

Leave a Reply