Learning Objective

- Different methods used in manufacturing aerosols

Manufacturing and packaging of aerosols requires specialized equipment and skills, special knowledge and rigid quality control. In addition to the equipment used for the compounding of liquids, suspensions, emulsions, creams and ointments, specialized equipment capable of handling and packaging materials at relatively low temperatures about –40°F or under high pressure must be available. The equipment is usually limited to packaging of aerosols.

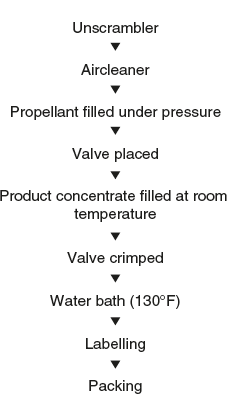

Pressure Filling

The concentrate may be chilled slightly (15–20°C) to reduce vaporization of any volatile solvent or propellant. The concentrate is added to an open container. The valve is crimped in place. The propellant is added under pressure through the valve. The filled container is passed through the water bath maintained at 55°C to check for leakage.

The apparatus consists of a pressure filling burette capable of metering small volumes of liquefied gas under pressure into an aerosol container. The propellant is filled into the burette through the inlet valve located at the bottom of the burette. The entrapped air is allowed to pass through the upper valve. The propellant is added into the container through the aerosol valve. The propellant flows into the container under its own vapor pressure. The flow stops when the pressure is equalized between the burette and the container. If additional propellant needs to be filled, then the burette is attached to a nitrogen gas cylinder and the pressure of the nitrogen gas pushes the propellant into the container.

Pressure filling devices can also be attached to a piston such that a positive pressure can always be maintained.

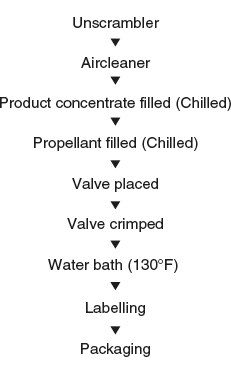

Cold Filling

The drug concentrate, which may be solution or suspension, is cooled to –30°C to –60°C. The container is also chilled and the cold concentrate is added to chilled (cooled) container. The propellant is added and the valve is crimped in place. The container is checked for leakage by passing into a water bath maintained at 55°C.

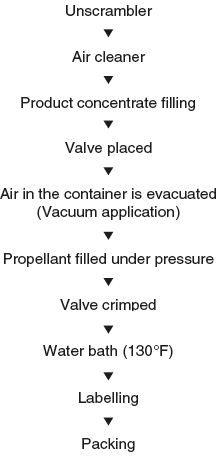

Compressed Gas Filling

Handling of compressed gases does not require any elaborate equipment. The compressed gases are under high pressure and hence a pressure reducing valve is required. The filling head is attached to a flexible hose capable of withstanding pressure of about 150 pounds per square inch and attached to a delivery gauge. The concentrate is filled in the container. The filling head is inserted into the valve opening and the valve is depressed. The gas flows into the container. When the pressure inside equals the delivery pressure, the gas stops flowing.

Leave a Reply