The amount of emulsifying agent used is dependent on the amount and type of oil to be emulsified. Oils can be divided into three categories: fixed oils, mineral oils and volatile oils.

- Fixed oilsOil: 4 parts by volumeAqueous phase: 2 parts by volumeGum: 1 part by weight

- Mineral oilsOil: 3 parts by volumeAqueous phase: 2 parts by volumeGum: 1 part by weight

- Volatile (aromatic) oilsOil: 2 parts by volumeAqueous phase: 2 parts by volumeGum: 1 part by weight.

(Note: Gum is the emulsifying agent or emulgent.)

These proportions are important when making the primary emulsion to prevent the breaking down of emulsion on dilution or storage.

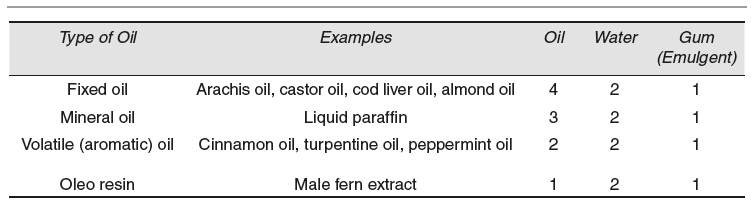

The ratio of oil to water to gum for a primary emulsion can be calculated using the formulae shown in Table 6.10. (The quantities for primary emulsion have been obtained by experience.)

Table 6.10 Primary Emulsion Formulae

There are two methods used in the preparation of emulsions:

- Trituration method: This includes the dry gum and wet gum methods.

- Dry gum or Continental method: In this method the emulsifying agent (usually acacia) is mixed with the oil before the addition of water.Acacia is triturated with the oil in a perfectly dry porcelain mortar until thoroughly mixed. A mortar with a rough surface must be used to ensure proper grinding action and reduction of globule size. After the oil and gum have been mixed, the amount of water required for the primary emulsion is added in small portions with continuous trituration. Trituration is continued in one direction until the primary emulsion is creamy white and a cracking sound is produced by the movement of the pestle. Other soluble liquid ingredients are then mixed into the primary emulsion. Solid substances such as preservatives, stabilizers, colorants and any flavoring agents are usually dissolved in a suitable volume of vehicle and added to the primary emulsion. The emulsion is then made up to volume with the remaining vehicle.

- Wet gum or English method: In this method, the emulsifying agent is added to water to form the mucilage and then the oil is slowly added to form the emulsion.In the wet gum method, the same proportions of oil, water and gum as given in Table 6.10 are used, but the order of mixing is different. Mucilage of the gum is prepared by triturating with water. The oil is then added in small portions with trituration. After the addition of the entire oil, the mixture is thoroughly triturated in one direction to form the primary emulsion. Other soluble liquid ingredients are then mixed into the primary emulsion. Solid substances such as preservatives, stabilizers, colorants and any flavoring agents are usually dissolved in a suitable volume of vehicle and added to the primary emulsion. The emulsion is then made up to volume with the remaining vehicle.

- Bottle or Forbes method: This method is employed for preparing emulsions containing volatile and nonviscous oils. Both dry gum and wet gum methods can be employed for the preparation.Since volatile oils have a low viscosity as compared to fixed oils, they require comparatively large quantities of gum for emulsification. In this method, the oil or water is first shaken vigorously with the calculated amount of gum. Once this has emulsified completely, the second liquid (water or oil) is then added all at once and the corked bottle is again shaken vigorously to form the primary emulsion. More water is added in small portions, with constant shaking after each addition, to produce the final volume.This method is not suitable for viscous oils as they cannot be thoroughly agitated in the bottle when mixed with the emulgent. When the intended dispersed phase is a mixture of fixed oil and volatile oil, the dry gum method is generally employed.

Leave a Reply