Learning Objective

- Different types of actuators

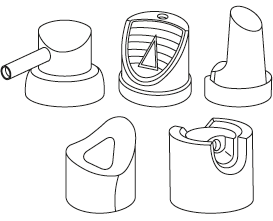

Actuators are specially designed buttons required for easy opening and closing of the valve. The type and quantity of the propellant and the design and dimension of the actuator determine the type of product discharge whether it is in spray or foam or a solid stream. Special actuators are available for use with pharmaceutical and medicinal aerosols that allow dispensing of products into the mouth, nose, throat, vagina or eye. The actuator is fitted to the valve stem. Depending upon the type of product discharge, actuators can be of the following types:

- Spray

- Foam

- Solid stream

- Special applications

Actuators can also be classified as mechanical break up actuators and non-mechanically break up actuators.

- Spray actuators are capable of dispensing the stream of product concentrate and propellant into relatively small particles. The stream is made to pass through various orifices ranging from one to three. The combination of vaporization of the propellant, orifice in the actuator and internal channels together deliver the spray in the desired particle size range. While using non-mechanical breakup actuators, the propellant concentration should be relatively high, in order to dispense the product in the form of spray. If propellant concentration is less than 50%, mechanical breakup actuators are required that mechanically break up the stream into spray by swirling through various channels in the actuator.

- Foam actuators consist of large orifices ranging from approximately 0.070 inch to 0.125 inch and greater. The orifices allow for passage of the product into relatively large chamber, where it can be expanded and dispensed through a large orifice.

- Solid stream actuators are similar to foam actuators, where the orifice is relatively large in order to dispense semisolids like ointments.

- Special actuators are those that are specially designed to deliver the medicament to the appropriate site of action like throat, nose, eye or vaginal tract.

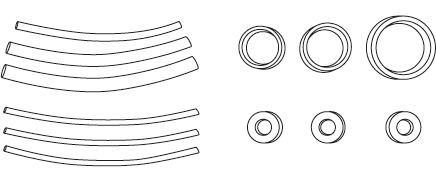

Different types of actuators are shown in Figure 12.6.

Figure 12.6 Different Types of Actuators

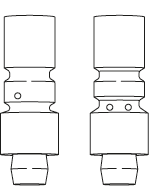

Stem: A stem (Figure 12.7) is a part of the valve assembly that controls the flow of the product. It may contain one to four orifices ranging in size from 1 × 0.010 inch to 4 × 0.027 × 0.045 inch. The stems are usually made up of nylon or delrin and materials like brass and stainless steel can also be used.

Figure 12.7 Valve Stem

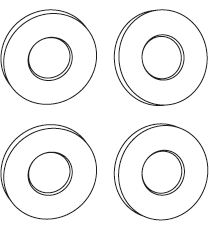

Stem gasket: The stem gasket (Figure 12.8) covers the stem orifice and in other words acts as an “on-off” switch. The gasket can be made of buna-N, neoprene, butyl or viton. Testing of the stem gasket is mandatory since the rubber may shrink or swell with different formulations. Choice of an appropriate stem gasket helps to prevent loss of the product due to leakage.

Figure 12.8 Stem Gasket

Spring: The spring (Figure 12.9) causes the valve to close after release of the actuator. It also serves to hold the actuator in place. Stainless steel valves are chosen for most of the aerosol products.

Figure 12.9 Spring

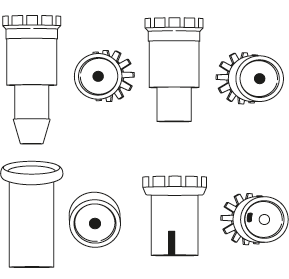

Valve body or housing: The housing encloses the stem, spring and gasket. It is generally manufactured from nylon or delrin and contains an opening at the point of the attachment of the dip tube. It acts as a secondary metering orifice. The opening may range from about 0.013 inch to 0.080 inch depending on the type of product to be dispensed. The housing may or may not contain another opening referred to as the “vapor tap” at the side or bottom of the housing. The presence of this orifice helps in expelling a dry and warmer spray, thus reducing the chilling effect of the product on the skin. Vapor tap allows the vaporized propellant along with the liquid product to escape. The vapor tap further produces fine particles, prevents valve clogging and allows the product to dispense satisfactorily in an inverted position. In the case of hydrocarbon propellants, it reduces flame extension. Different types of valve housing are shown in Figure 12.10.

Figure 12.10 Different Types of Valve Housing

Dip tube: The dip tube (Figure 12.11) draws the product up into the valve and helps in delivering the formulation. It is made from polyethylene or polypropylene. The viscosity of the product and the delivery rate desired determine the diameter of the dip tube. The usual diameters range from:

Standard : 1/8″ (0.122″) inside diameter

Large : 3/16″ (0.190″) inside diameter

Jumbo : over 1/4″ (0.260″) inside diameter

Capillary : < 0.060″ inside diameter

The dip tubes are notched at the bottom to prevent closing off at the bottom of the can.

Figure 12.11 Dip Tubes

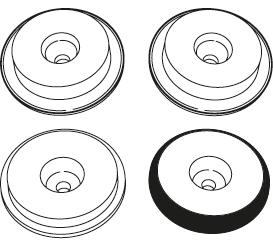

Ferrule or mounting cup: The ferrule or mounting cup (Figure 12.12) holds the valve parts together and attaches the valve properly to the container. It can be made from tin-plated steel or aluminum. The underside of the cup should be protected from corrosion by the aerosol contents. This can be achieved by a single or double epoxy or vinyl coating. Softer metals such as aluminum or brass are used for ferrules with glass containers and small aluminum tubes. The ferrule is attached to the container either by clinching the metal under the lip or by rolling the end under the lip of the bottle.

Figure 12.12 Mounting Cups

Leave a Reply